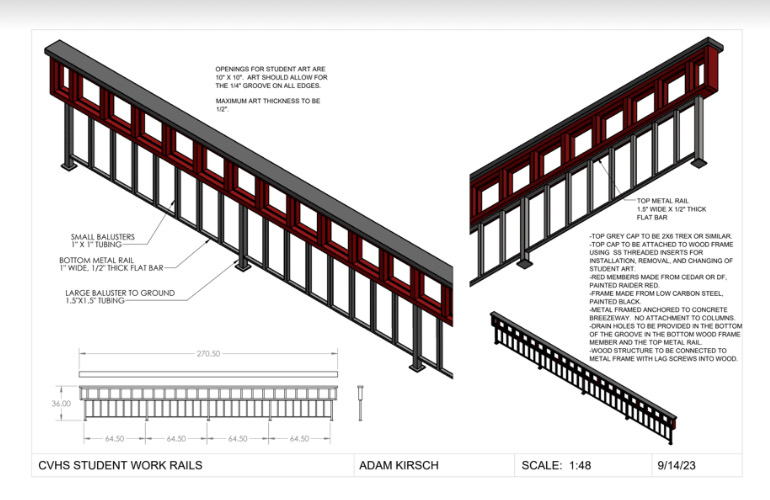

If you’ve walked around our campus recently, you might have noticed a brand new student-made project. Between the E wing and the library, a fence or a railing has been installed between the walkway and the creek. Previously a ugly wired fence was the only thing protecting the berries from students but through the hard work of many CV students, a new railing designed and made by High Schoolers was installed this year. The Crescent Crier interviewed the team to find out more about this project.

Why did you choose to do this project; what inspired your team?

When we had been given this project the design was already made. It was a compelling project because it required a range of skills in both woodworking and metals. The railing project is also a unique opportunity to leave a positive impact on our school. With the opportunity to display art we are proud to showcase our peers’ work in an organized and aesthetically pleasing manner.

What was the process of creating that project; who was involved; how long did it take?

The original team of Andre, Wyatt and Sarah started this project at the beginning of second semester in the 23-24 school year. Ben and Jonas joined soon after. The designs for the railings have already been made and approved by the district thanks to Mr Kirsch. The main elements of the project are the wood, metal, and removable trex top. Our original goal was to complete the railings by the end of 2023, but due to the scale of this project we were only able to install one section by the end of 2023. The project is only near completion now due to the dedication and discipline of the entire team. It also helped to have the support of the metals class, Ivan, Alden, Evelyn, Autumn, Francesca and many others. The project is set to be complete and it will be filled with CV art!

How much did it cost to create this?

The cost was around $1,000. This rough estimate includes the metal, wood, paint, screws, and original trex top.

Is there anything you learned from this project?

The support and hard work of multiple people helps a daunting task seem achievable

You have to be very flexible to complete large projects like this, because even with meticulous planning, things will go wrong and designs will have to be changed. You must be able to react to changes well and be creative in coming up with solutions to solve these unexpected problems. If you’re too set on things being done in the specific way that was originally planned, you will be disappointed. But if you can work through the problems and difficulties while being flexible, the project will be enjoyable and the final product will be good.

Drilling through metal sucks – Alex Christian

Is there anything else you’d like to say about this project?

Things will inevitably go wrong on a big project like this, so extra time must be planned in in order to correct mistakes. Also, with a fixed amount of work time and people, timelines have to be very flexible, as we found out, when we had to change our timeline numerous times over the course of the project. – Wyatt

The best parts of this project were when pieces came together following mistakes. When you are able to kind of laugh at the mistakes, and then find solutions, it stops being frustrating and becomes a natural and sometimes even enjoyable part of the project. -Ben

Sometimes you have to work above and beyond what you think you should because projects have to get done. We had to spend our entire Memorial Day welding the railing together because we had to hit a milestone on our project and sometimes you just need to get something done, no matter how long it takes. – Jonas